CAD Engineering of Complex Machined Parts

Machined-part concepts realized

CAD engineering at CED focuses on combining creativity with function-improving innovation. Starting with your specifications and ideas, our highly trained CAD/CAM software team will work with you through a collaborative process. One that begins with detailed variations of what you have in mind—and ends with realization of your working prototype or part.

CED’s 9-step CAD process for machined parts:

1. Strategy Planning

We begin by working with you to define performance goals and important design parameters. We then brainstorm to come up with innovative ways to address any machining issues. This can include improving machined part appearance, improving part life, and modifications as needed to avoid potential patent infringement.

2. Preliminary Modeling

Sometimes, pre-approval of a concept may be necessary, requiring a concept model to demonstrate or validate a design. Creating a preliminary model can help to clearly communicate a design direction. It can ALSO provide a foundation structure for fitting ancillary components like gears, wires, tubes, springs, and more.

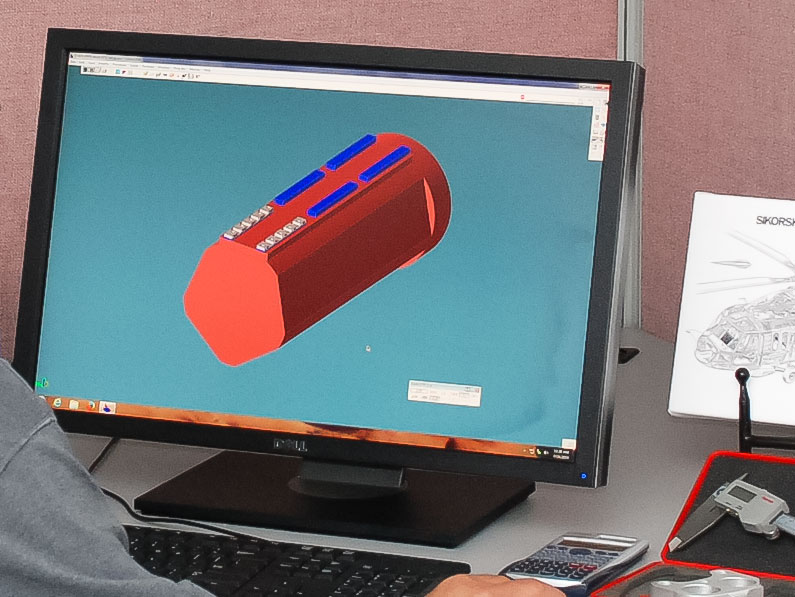

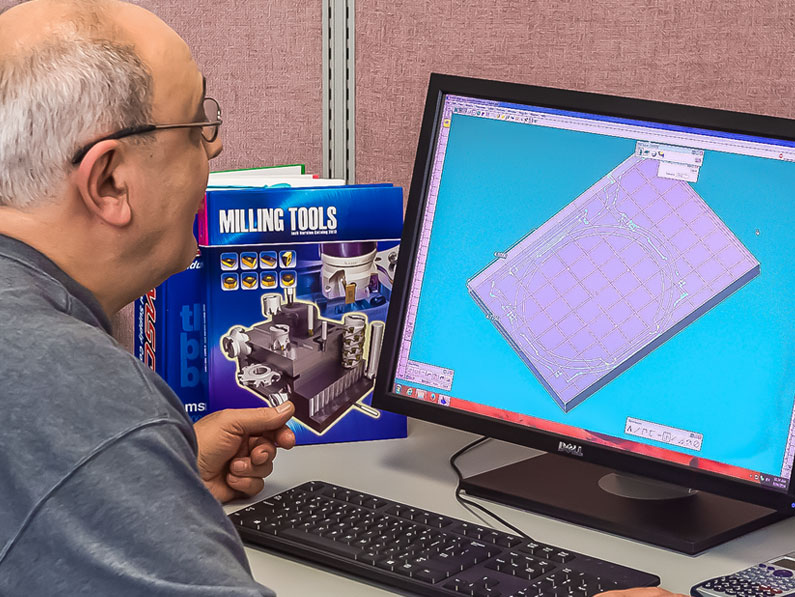

3. Concept-Approved CAD Design

With an initial direction reviewed and approved, we deploy the latest CAD technology to create a balanced first-pass solution. Our abilities to create an aesthetically pleasing machined part is matched by our experience in engineering solutions that deliver you maximum production efficiencies.

4. Engineering

Following our approved CAD effort, we create tooling-ready CAD models that include perspective drawings, 3-D styled renderings, and cross section views as needed to better communicate structural details.

5. Prototype Development

A dimensionally accurate, functioning prototype of your part is then created using 3-D Rapid Prototype Printing or one-off CNC machining as applicable. From there, secondary and more critical design assessment can be conducted to ensure the solurtion delivers the performance characteristics and structural integrity desired.

6. Prototype Evaluation & Refinement

Feedback from you and our tream is combined with a functional evaluation of the prototype that includes manufacturability. We then implement any warranted improvements to arrive at a final, approved plan ready for machining production.

7. Design Documentation

Careful recording of the entire process and final manufacturing strategy ensures repeatability and accountability. These records include a materials bill, description of process and details, elevation and 3-D CAD drawings, perspective drawings, CAD data, interior details, surface specifications, and animated video clips if necessary to illustrate crucial function.

8. Machine Tooling

Our proven expertise in complex machining and tooling ensures your design is translated into parts manufactured as efficiently and quickly as possible, while adhering to any applicable industry-mandated guidelines or requirements.

9. Quality Assurance Adjustments

Once machining of your part begins, first-run inventory is reviewed, measured, tested, and evaluated to detect any problems. We also investigate to determine if any additional cost-reduction or part enhancement is possible. Our quality commitment to you: we never stop looking to make your part better, faster, and for less.

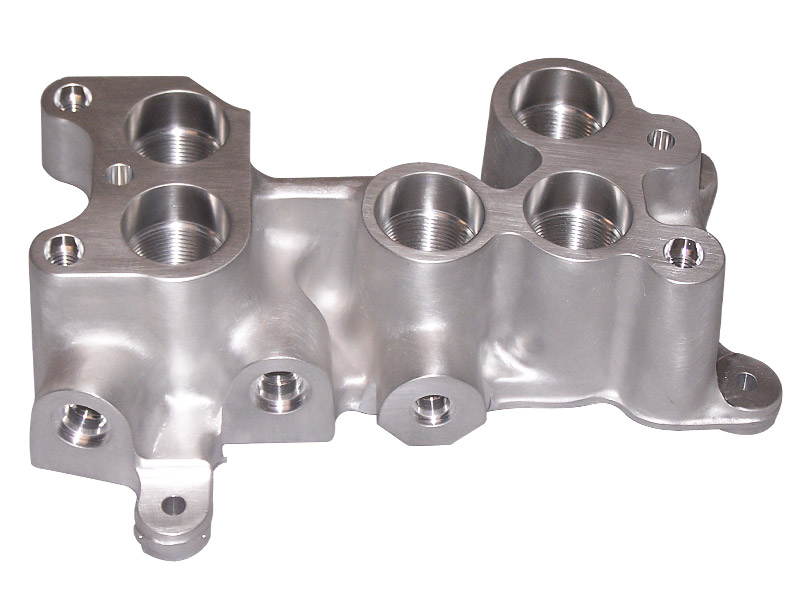

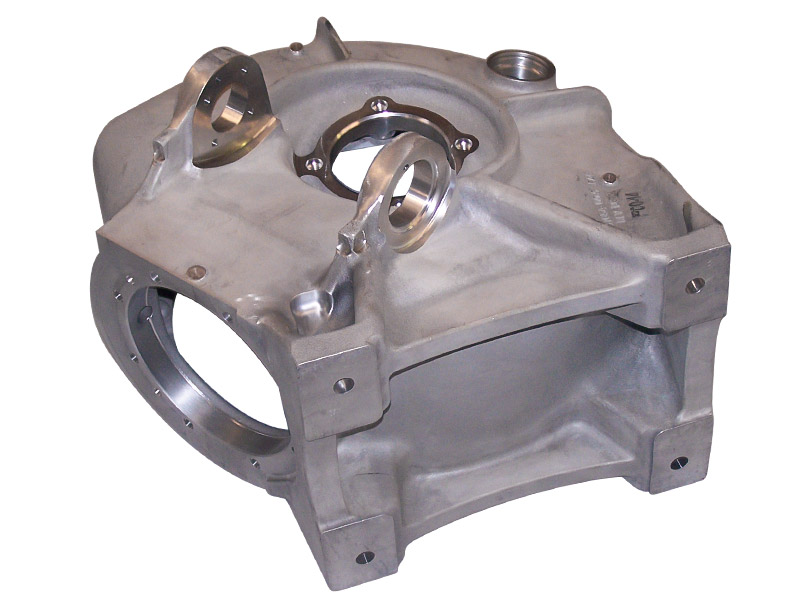

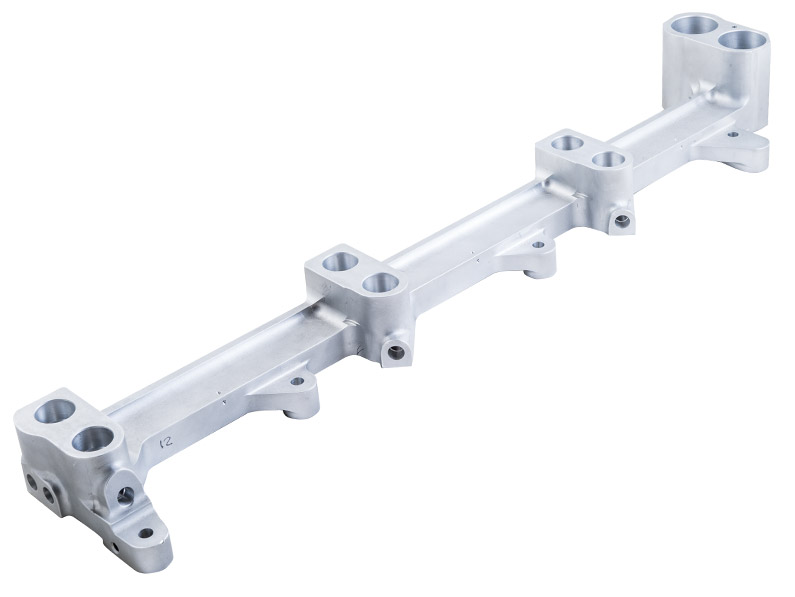

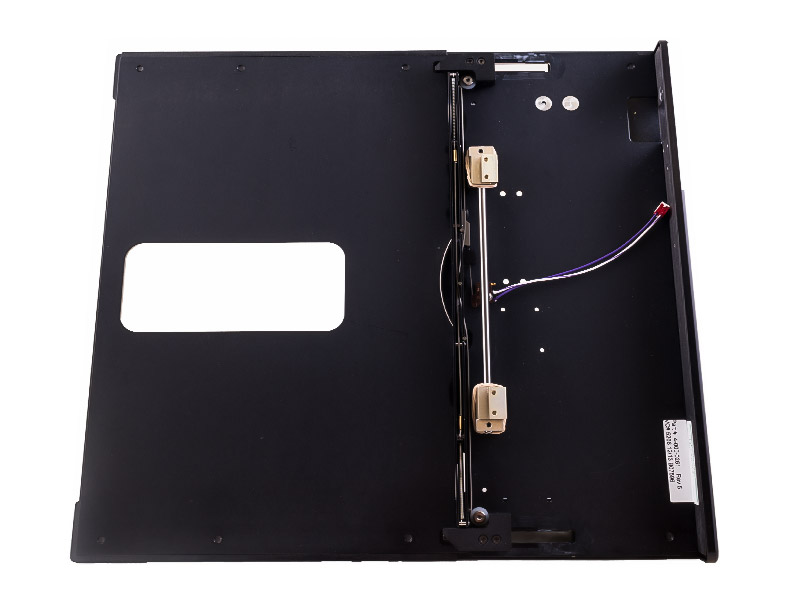

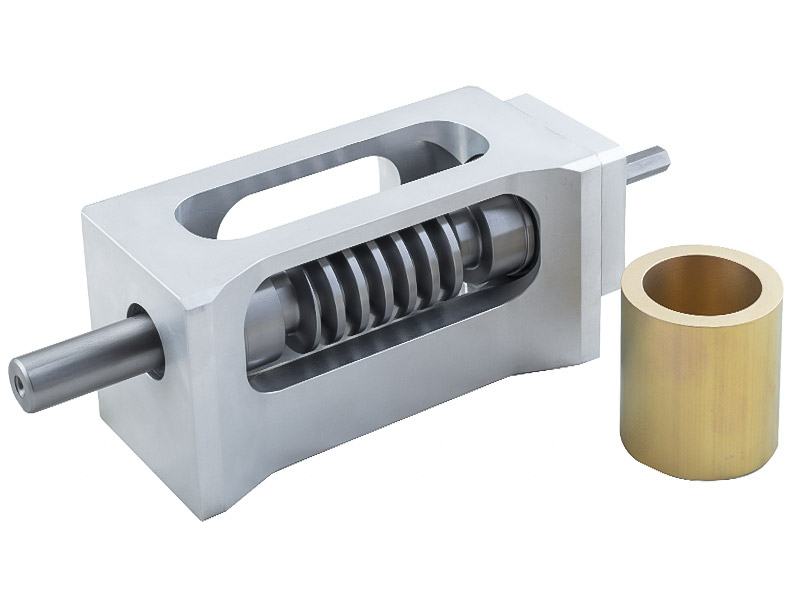

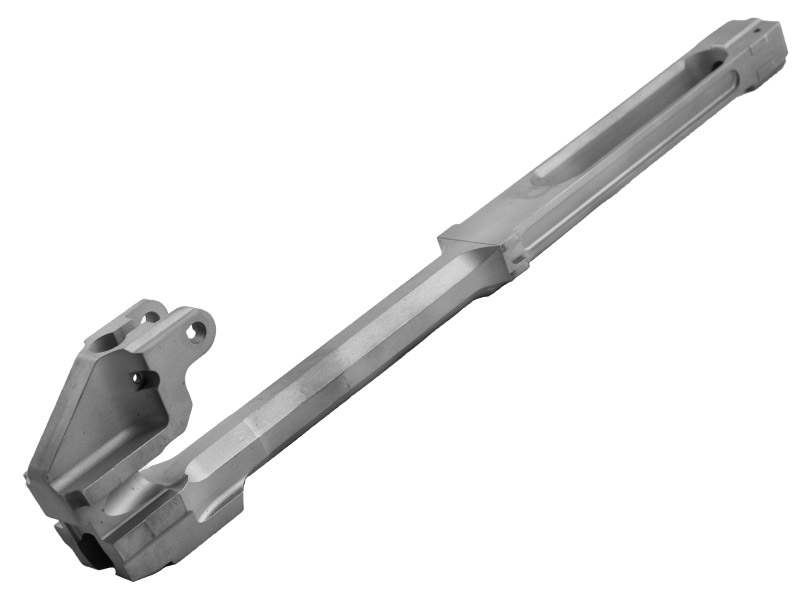

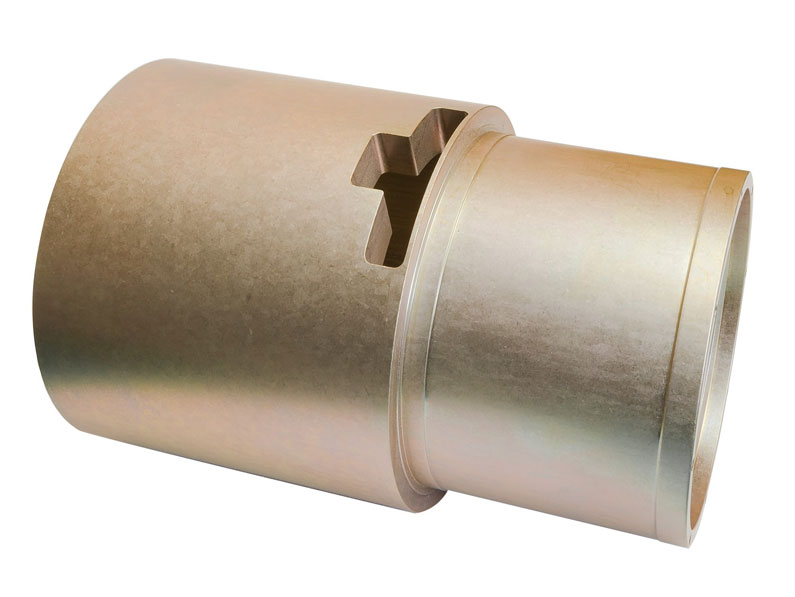

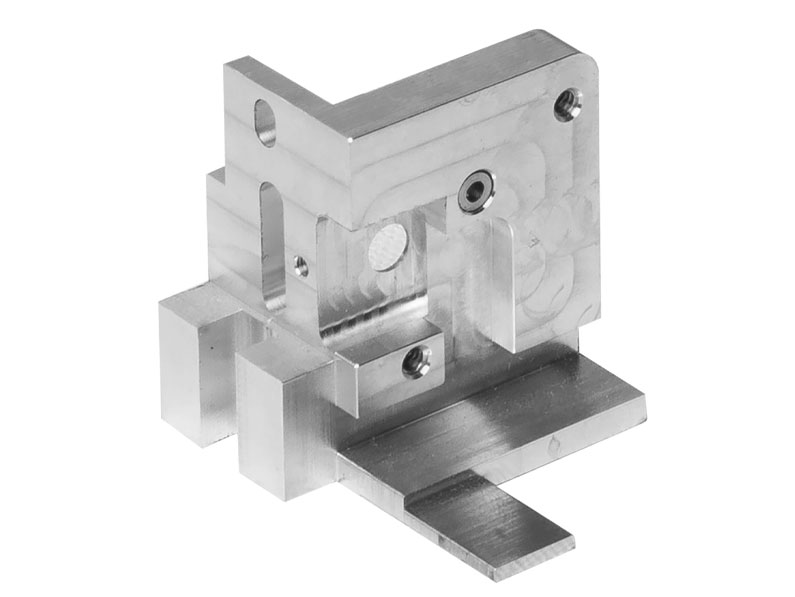

CED Machined Parts and Components Gallery

(click images to enlarge)

Contact CED Services

Have a question? Need a quote?

Call or email us today!

203-828-6528

6 Reasons to consider CED :

1. Diverse Capabilities: Our advanced equipment and AS9100D/ISO9001:2015 Certificate ensure specified-precion for parts and subassemblies used in the most demanding industries.

2. Customer Dedication: Experienced professionals focused on your part program success.

3. Lower Cost: Consistently higher-quality parts—machined for less.

4. Convenient Location: Nestled in Oxford, Connecticut, USA — only 1 mile from Oxford Airport.

5. Vendor Upgrade Program: Our 3-step program eliminates vendor-switching nightmares.

6. Reputation: Our world-class precision and service have earned praise and trust from our customers...

Read what CED clients say:

“We enjoy our relationship with CED for several reasons namely, that they have the expertise that our products require and the equipment that can efficiently produce it. Their decision making people are skilled in their areas of expertise. This, plus their attitude of "what can we do to help you" is a combination that has served us well.”

Tom Chiaramonte, Engineer | Triumph Actuation Systems

“CED has consistently proven they can produce top quality fabrications. The staff at CED offers outstanding Engineering support. The cycle time associated with design, prototyping and assembly verification is greatly reduced due to CED's commitment to quality and service.”

Tom Farbizio , Engineer | Hologic Inc.

Consulting, Engineering & Development Services, Inc.

3 Fox Hollow Road,

Oxford, CT 06478